By Leslie Faughnan

The ultimate silent intruder is gas. Undetectable except, sometimes, by the human nose or by specialized detectors. With the right sensor for that type of gas. Which could be noxious or even lethal. Or just toxic. Or flammable or even explosive. Smoke is better. Control room people can see it on screen, if there is visual monitoring. And detectors are cheap and cheerful.

Some other types of gas are not usually harmful, cause little bother. But that includes refrigerants from leaks in equipment, which are expensive to replace and leakage can lead to malfunctioning.

The key point about gas detection for security companies is that they are missing a golden opportunity, according to Dr Lorcan Maher, Managing Director of MURCO, a manufacturer of advanced gas detection equipment. "Gas detection is a fast growing and profitable business area. It is being driven by more safety and occupational health legislation in most countries and also by the sheer expense of replacing modern, environmentally friendly refrigerants in food distribution and air conditioning, again driven by tighter regulatory regimes."

Advanced gas detection today is based on highly accurate, long life electronic units, with sensors that can cover a broad spectrum of gases or target specific or difficult to detect gases. "For a security company, whether supplying and installing or offering a monitoring service, the key point is that they are networkable. Gas detection units can be incorporated into any security monitoring system, wired or wireless."

Dr. Lorcan Maher goes on to suggest that gas detection is as obvious a complementary role in any security planning and setup as, for example, smoke and temperature detection and fire prevention and alarms. "The trend for the future is already clear as these monitoring tasks are being incorporated in modern digital Building Management Systems, which are certainly gaining a lot of ground in new building where they can be designed into the specifications at an early stage. But why should the security industry yield market share to facilities management?"

"The reason it is doing so, of course, is that security people and companies have always regarded themselves as specialists. Quite rightly, but the trouble is that in doing so they have become bound into a traditional range of risks. Yet this has all undergone what the IT jargon calls a paradigm shift with the advent of digital monitoring systems across the board, from the new generation of micro-cameras and remote monitoring over the Internet to alarm devices pre-set to call mobile phones [cellphones] or even send SMS text messages. Todays and tomorrows world is digitally joined up. Any system or service for the security monitoring of buildings and enclosed places of all kinds has to be integrated and comprehensive to compete in an ever more demanding and sophisticated market place."

His message to security companies is simple and blunt -- embrace and include gas detection and all other risks capable of being monitored electronically or risk being overtaken by new and broader spectrum systems and services based on todays smart building and facilities management systems. Active security monitoring services may survive longer but with smart modern electronic systems, passive monitoring will be completely automated as part of a total facilities management type of service. "Its appeal to the customer is going to be based on that very integrated, electronic, all risk market strategy that the security industry is still spurning, possibly because it fears losing its specialist cachet," Dr Maher warns.

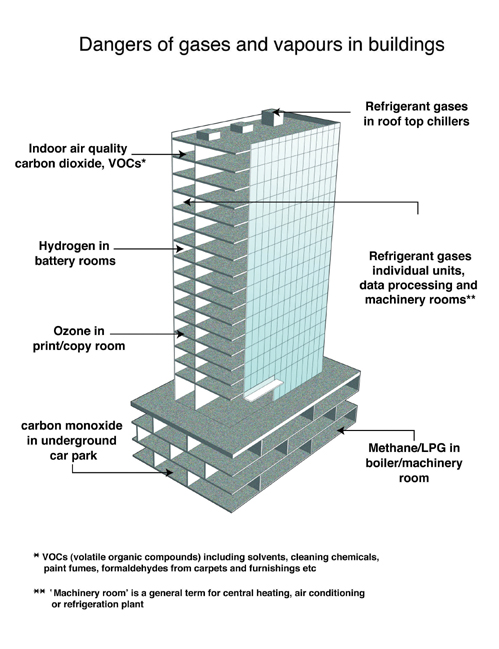

Is this gas detection market really that appealing or that important? Absolutely, Dr. Maher insists, pointing out that almost every building has a gas detection problem of some sort. Offices and commercial building typically have, for example, carbon monoxide in underground car parks and those valuable refrigerant gases in air conditioning or data rooms and food retailing or hotel/restaurant food storage. Other indoor air quality pollutants most mandated under public or employee health regulations, including Carbon Dioxide and VOCs [Volatile Organic Compounds], methane or LPG in boiler rooms, cooking and heating applications. There can even be hydrogen risk in UPS battery arrays.

|

|

|

Figure 1. Dangers of gases and vapours in building (Source: Murco) |

Industrial and municipal buildings have many problem gases such as hydrogen sulphide, ammonia, and methane in sewage treatment, chlorine and ozone in water treatment or bottling applications, ethylene in fruit storage, acetylene and oxygen for welding, solvents, alcohols and VOCs in industrial processes and CO2 in brewing and wineries. Public buildings such as cinemas, hotels, universities, airports, etc. share all of these gas risks, as do passenger ships. The added dimension is simply that being public they bring in an even wider range of regulatory compliance issues in almost every jurisdiction.

The gas detection business is increasingly being driven by legislation, against a background of increasing awareness of the risks and the knowledge that for over two decades there has been satisfactory monitoring technology. As that gas sensor technology has developed and evolved legislators and national health and safety bodies have mandated appropriate gas risk monitoring anywhere there are people or even animals.

Safety at Work

Occupational health and safety legislation is probably the principal legal area driving gas detection because it covers people who are potentially at risk for longer periods than visitors to any building or facility. This type of regulation universally requires that workers be not exposed to toxic harmful gases, including refrigerants, above recommended limits. These regulations are normally policed by responsible bodies such as a Health and Safety Executive. Exposure levels are determined and published in most countries and workers should not be exposed to higher than allowable levels. Flammability regulations are also common and require that monitors be used if flammable gases such as methane, LPG, propane, butane, hydrogen etc. are present.

An important point is that fixed gas monitoring systems allow compliance and can be used to maintain records of compliance in case of inspection, dispute or litigation. Dr Maher draws attention to the huge opportunity here for security companies to offer added value through integrated systems. "Traditional security can only show its value when a threat has been, we all hope, successfully averted. By working with integrated, high tech monitoring systems, there is an opportunity to add value through the kind of monitoring reports that more and more clients require to satisfy compliance authorities."

Environmental Laws and Regulations

Refrigerant leakage plays a big part in the gas detection market. The background is the increasing concern worldwide about ozone depletion and global warming. The legislation started with the Montreal Protocol in 1987, which formalized a response to the damage being caused to the ozone layer by ozone depleting substances, of which traditional refrigerants were a significant constituent. With the subsequent international phase-out program for CFCs and HCFCs, the replacement cost of refrigerant leaks started to become a concern but even still few operators took the positive step of installing stationary refrigerant monitors.

The ISO Standard 5149: 1993(E) was the international response to the Montreal Protocol and Ozone Depletion. It updated previous Standards relating to air conditioning and refrigeration and incorporated the specific requirement to use gas leak detectors. It applies in all member countries of the International Standards Organization in Europe, the U.S.A. and such major Asian countries as China, Japan, Korea, Singapore, India and Pakistan. A number of countries worldwide including the U.S.A., the U.K., Netherlands and South Africa have also their own supplementary regulations or standards requiring the installation of fixed refrigerant monitors. Europe has specific laws and Standards and in 2000 the EC introduced a law binding in each member state (Regulation 2037/2000) requiring that all precautionary measures practicable be taken to reduce leakage of refrigerants.

The Standard EN378 introduced at the same time details such steps and requires the use of fixed leak detectors in all refrigeration and air conditioning machinery rooms. In addition, strong warnings are included on the dangers of refrigerant leaks into occupied spaces. The options put forward by the manufacturers now generally include the use of fixed leak detectors

The F Gas law came into force in Europe this year and requires that gas monitors be installed in certain refrigeration and fire suppression systems using fluorine containing substances.

In the U.S.A., the ASHRAE 15 standard was introduced and similarly required the use of refrigerant leak detectors. The requirements in ASHRAE 15 were incorporated into the Uniform Mechanical Code and subsequently International Mechanical Codes.

Security Industry Advantage

The security industry has a potentially enormous advantage in exploiting these new opportunities. In many cases they are already working in a particular building with monitoring and control systems and need only add gas detection sensors to their networks. They also have the expertise in monitoring and alarm systems and are generally required to service and upgrade these. Gas detection is a natural add-on.

Manufacturers such as Murco offer smart detection systems with sensors for all gases likely to be encountered. These have almost universal compatibility and can be added to a system, controller, BMS, or network by using their analogue or digital outputs or data ports.

Smart Range of Systems

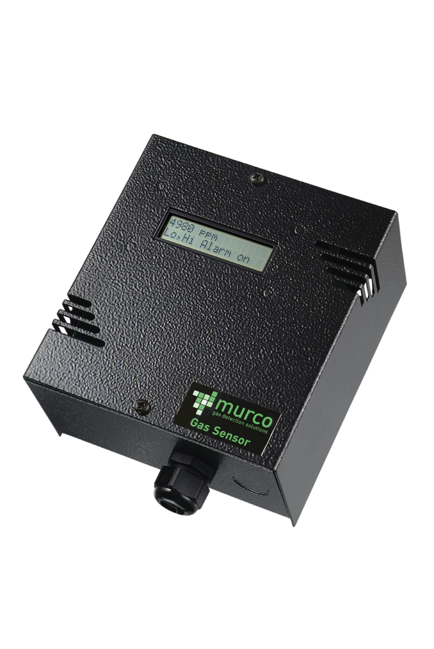

Dr Lorcan Maher confirmed that MURCO has launched a new generation of gas detection equipment, to complement what is already the most comprehensive range gas leak detection equipment on the market. Sophisticated yet robust and reliable, these highly successful gas alarm systems are now used in thousands of installations worldwide.

The Murco Sensor Transmitter range includes state-of-the-art catalytic, semiconductor, electrochemical, and infrared models to detect most gases in an area, room, zone, airspace or airflow. It has analogue, digital and data port facilities. The latest MURCO MGS model is also a transmitter with analogue and digital outputs

|

|

|

|

| The latest MURCO MGS (Photo by Murco) |

ST-IAM sensor (Photo by Murco) |

Typical control panel (Photo by Murco)

|

Both systems can interface with most BMS, alarm or control systems. They can also function as stand-alone gas detection system using the extensive range of Murco panels. All have visual and audible alarms and relays for control or remote reporting. All Murco units incorporate constant power and system fault monitoring as standard. Available for all refrigerants and most other problem gases, they are used extensively to ensure compliance with international conventions and regulations.

Leslie Faughnan is a science and technology journalist based in Ireland.

For more information, please send your e-mails to swm@infothe.com.

ⓒ2007 www.SecurityWorldMag.com. All rights reserved.

|